RDF Manufacturing Plant & Process Flow

RDF stands for Refuse Derived Fuel. This fuel is produced from combustible components that the industry calls Municipal Solid Waste – MSW for short. This waste, usually taken from industrial or commercial sites, is shred, dried, baled and then finally burned to produce electricity.

RDF stands for Refuse Derived Fuel. This fuel is produced from combustible components that the industry calls Municipal Solid Waste – MSW for short. This waste, usually taken from industrial or commercial sites, is shred, dried, baled and then finally burned to produce electricity.

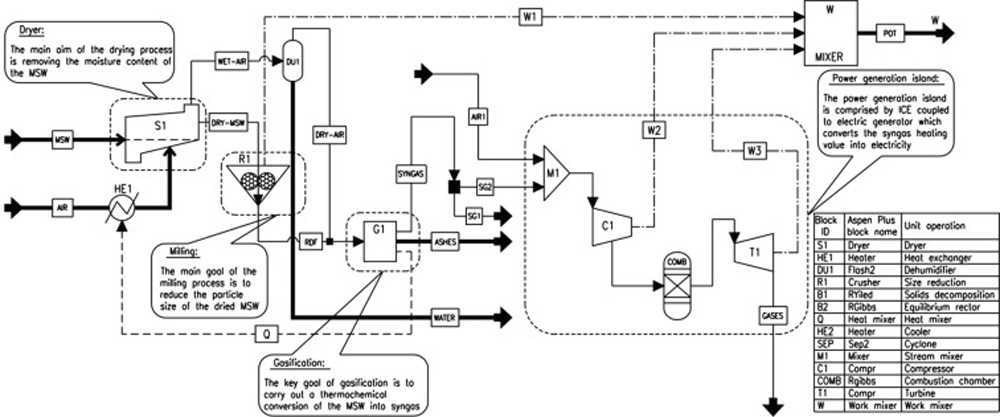

Refused Derived Fuel (RDF) is a fuel produced from unrecoverable materials of municipal solid waste (MSW). It is largely made up of compostable components such as plastics and biodegradable wastes that are processed to obtain a product with a high calorific value. RDF is a great substitute for fossil fuels like coal or oil. It is used worldwide to produce electricity by burning alongside traditional sources of fuel in coal power stations. It can be also used in the cement kiln industry or other co-incinerations.

The use of RDF benefits the environment by greatly reducing the emissions of CO2 from the burning of fossil fuels. Without this energy recovery technology, non-recyclable refuse would simply end up in landfill or get incinerated, with a negative impact on our environment.

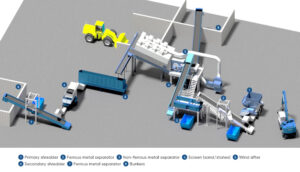

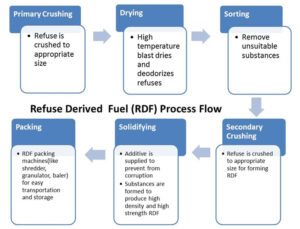

At waste-to-energy (WTE) facilities like Waste Power Indonesia, the collected wastes go through a series of processes to meet requirements for particle size moister content and non-combustible content. Firstly recyclable materials like metals, wood, cardboards etc. and non-combustible materials like glass are removed. The residual wastes are then shredded for multiple times to reach the dimensional specifications. The shredded pieces will then be dehydrated to control the moisture content and at last can be packed in bales in order to optimize its handling and storage. Pre and Re-shredding is the nucleus of RDF production plants with various shredders and granulators.

Municipal solid waste (MSW) and commercial and industrial (C&I) waste contains many different materials that need to be separated mechanically into a high- and a low-calorific fraction. This process involves shredding, screening and classifying of the material. Metals, inerts and organics are removed; light fractions with high-calorific value (e.g. plastics, textile and paper) remain.

Refuse Derived Fuels

Refuse derived fuel (RDF) is a valuable substitute for primary materials such as gas, oil and coal.

Refuse derived fuel (RDF) is a valuable substitute for primary materials such as gas, oil and coal.

Municipal solid waste (MSW) and commercial and industrial (C&I) waste contains many different materials that need to be separated mechanically into a high- and a low-calorific fraction. This process involves shredding, screening and classifying of the material. Metals, inerts and organics are removed; light fractions with high-calorific value (e.g. plastics, textile and paper) remain.

In order to optimize the output quality shredding can be combined with:

Sorting and separation according to:

- size and form: drum screening, 3D-screens, fine screens

- weight and form: air separation, ballistic separation

- special material properties: ferrous metals, non-ferrous metals, optical separation of pre-defined fractions, e.g. plastics/PVC, wood, glass

Drying and pelletizing:

- Thermal drying (belt dryer, drum dryer)

- The result is a homogeneous refuse derived fuel ready for pelletizing

Additionally, valuable fractions, such as metals, can be removed early in the process and appropriately recycled. The metal fraction from the ferrous metal separator, often with plastics or textiles still adhering to it, can be cleaned. Composite materials can be broken down with a shredder. In the end, the steel scrap and non-ferrous metals can be recovered with a superior purity of 98% – perfect for use in the steel industry or re-processing in foundries.