PT Bali Citra Metro Plasma Power (PT BCMPP)

BAHAN BAKAR ALTERNATIF “REFUSE DERIVED FUEL” (RDF)

THE COMPANY AT GLANCE

PT Bali Citra Metro Plasma Power (PT BCMPP):

Is a renewable energy solution Company. Convert the Municipal Solid Waste within a city into electricity.

We aim to:

• Convert the Municipal Solid Waste within a city into electricity.

• Assist to eliminate huge doping of waste into the environment.

We build:

• A renewable Power Plant using MSW as the feedstock and a gasification plant as selected technology

We distinguish ourselves by using gasification as selected technology.

We provide waste management that leads to innovative advantages and considerable benefits for Bali Island & Solo City (Java)

We inspire trust through:

• Reliability of technology • Track record of shareholders

BUSINESS BACKGROUND

Waste Conversion to Energy using Gasification Technology

Uncontrolled accumulation of waste:

• In landfills, uncontrolled accumulation of waste within a period of time can lead to deposition solution / fluid-containing compounds which have a secondary value but also harmful substances which usually and typically composed of heavy metals, organic pollutants and pathogens.

• This will happen especially if there are no waste separation processes (such as the separation of drugs or medical devices , as well as a battery, heavy metals, chemicals such as pesticides, etc.).

• Therefore, it can cause harmful substances that will contaminate animals, plants and humans through various types of media.

The Solution is by:

• Adopting gasification technology to process the collected waste in an integrated waste disposal.

• It continues to the next step which is the process of gasification of waste and converting it into energy. • This process is the technological solutions in reducing the amount of landfill waste accumulation and daily garbage gasification process.

• Additional benefit from this gasification process is the production of electricity generated from garbage gasification process itself.

MARKET HIGHLIGHT

Waste in Indonesia becomes national issues, as municipal solid wastes in almost all cities in the country accumulate mountainously. This happens due to lacking of waste management system that has not been implemented properly and precisely. Therefore, an investment in this type of project will provide good business opportunities and social solutions. Availability of feedstock from wastes in Indonesia is therefore enormous, i.e. Jakarta has 8.000 tons per day, Semarang produces 5,000 tons per day, while Solo has 500 tons a day, Tangerang and Makassar each produces 1,500 tons a day, and Bali is at 3,000 tons per day. It is so the same with the other cities in Indonesia, therefore continued feedstock in each city is generally assured.

PROJECT BRIEF

- Preliminary

Waste is the result of activities that must be managed properly and correctly so as not to pollute

environment. Waste materials contain a variety of chemical compositions, which when reacted with each other or with air, will have the potential to produce greenhouse gas (GHG) emissions.

Until now, most of the waste management in Indonesia still applies the conventional system, namely:

Patterns of collection, transport, and disposal at the landfill without any upstream and final processing.

The landfill area is getting bigger with the increase in waste generation which is in line with the increase in population and waste reduction activities at sources that are not yet optimal. Efforts to reduce waste generation without losing its use value and economic value are now becoming future waste management challenges for the Government of Indonesia.

Waste is a renewable energy source. The type of combustible waste hasthe potential calorific value is high enough so that it can be used as an alternative fuel, Salah One form of utilizing waste is as an alternative solid fuel or called Refuse Derived Fuel (RDF).

Refuse Derived Fuel is a solid fuel derived from combustible waste such as waste, paper waste, plastic waste, and others. RDF is processed according to guidelines and regulations, especially to achieve high calorific value.

- Process of processing waste into RDF

The urban domestic waste is divided into two, namely: combustible waste (combustible waste).waste) and non-combustible waste. Combustible waste consists of:

organic components, paper, plastic, rubber, wood and cloth, while the combustible components are metals, glass, and others such as sand, stone, etc.

In order to meet the RDF criteria, the waste must be conditioned first through several treatments as shown in Figure 1 below:

- Utilization of RDF in PLTU

Boilers as heat generators and power plants can use RDF fuel in the form of: pellets or in bulk form. The emission characteristics of RDF pellets are superior to those of coal and produces lower emissions such as NOx, SOx, CO and CO2 (Salman Zafar, 2014).

RDF is an alternative and renewable resource. The main advantages of RDF are conversion of waste into energy that helps in the effective handling of urban household waste, solid waste management, and elimination of fossil fuels. The production and utilization of RDF leads toa green environment is one of the most profitable ways of solving integrated waste management, as one of the tactical elements for reducing CO2 emissions coming from fossil fuels, and one of the capital to increase renewable energy.

The use of RDF in the boiler is mixed with coal; the maximum use only replaces 17%coal capacity.

- RDF SPECIFICATIONS for PLTU

The recommended product form is in the form of fluff (20 – 50 mm)

- Residue of RDF in PLTU Boiler

In the case of RDF combustion, the non-combustible form of the material becomes important.

Glass particles, for example, will introduce sodium into a completely different system than sodium from salt. Lime from paper coatings will not act the same as CaO from other sources. Furthermore, particle size may be important. For example, large particles of glass can produce nuclei which promotes the slag forming reaction. In the waste selection process, materials from glass is like a glass bottle, broken glass becomes a target that must be sorted out before continuing the process drying to RDF. Residues from burning RDF are increasingly being minimized.

The first city in Central Java in Indonesia is already in progress of building a renewable Power Plant using MSW as the feedstock. A combination of bio-drying and gasification process is the selected technology to be used by the municipal city. The city’s WTE will process approximately 23 tons per hour (545 tons per day) of MSW to generate electricity of 5 MW net.

- The supply of feedstock to the plant is obtained from the government of the municipal city and is secured by a contract for the next 20 years. The electricity will be sold to PLN using feed in tariff (FIT) of US$ 0.1335/kWh flat in a 20-year contract. The plant requires an area 25,000 m2.

- The Front-End Engineering Design (FEED) still proceeds according to the plan and was completed in September 2017. Deep Feasibility Study, Interconnection Study and UKL / UPL was completed in September 2017. Other licensing documentations are in place.

- Power Purchase Agreement (PPA) with PLN was signed on 28th of December 2018. PPA is now effective.

- The Financial Close was attained on 5th of December 2019.

- Development is on-going now and has reached a progress at 71.5% as of February 2

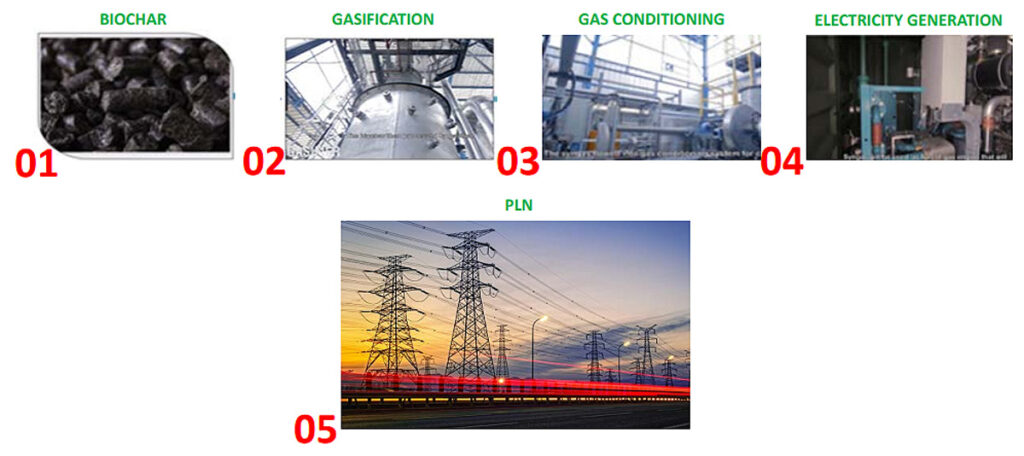

THE TECHNOLOGY – HOW IT WORKS

- Gasification Process

The core process of the WTE power plant will take place at Gasification Island by transforming the Biochar in a thermo-chemical process to obtain a combustible gas mixture known as Synthetic Gas or Syngas. Operating temperature of the gasifier will be around 1000°C and at slightly above atmospheric pressure. The gas produced contains important amount of hydrogen, carbon monoxide, and methane along with nitrogen, carbon dioxide, water steam, ash, and other compounds in small quantities. - Gasification Conversion

Operating temperature of the gasifier will be around 1000°C and at slightly above atmospheric pressure. The gas produced contains important amount of hydrogen, carbon monoxide, and methane along with nitrogen, carbon dioxide, water steam, ash, and other compounds in small quantities. Undesirable products (by products) removed from the gas stream during the conditioning and cleaning processes are used to produce heat that will be used in various stages of the plant.

ELECTRICITY PRODUCTION

The power generating devices will be used to convert syngas to electricity with an output power of MWs. The output of the gas stream during the conditioning and cleaning process can be reused to produce heat which will be needed at various stages of the process.